It looks like you're visiting from the United States.

To ensure the best experience and correct pricing, please visit our dedicated US website.

Go to DUKE US site

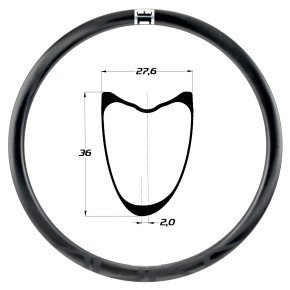

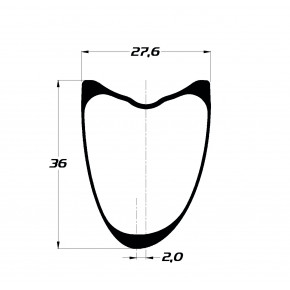

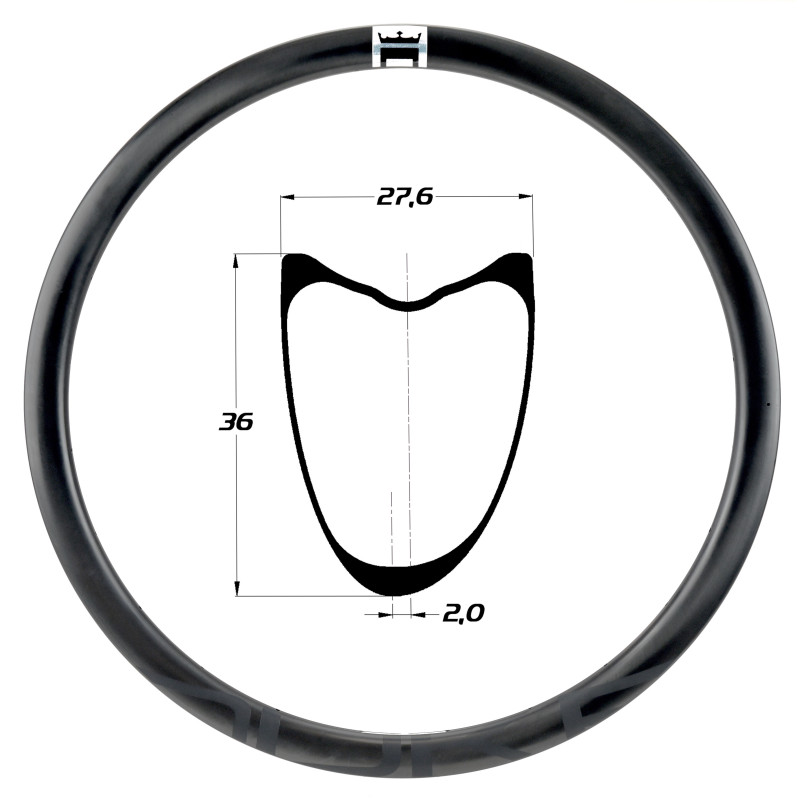

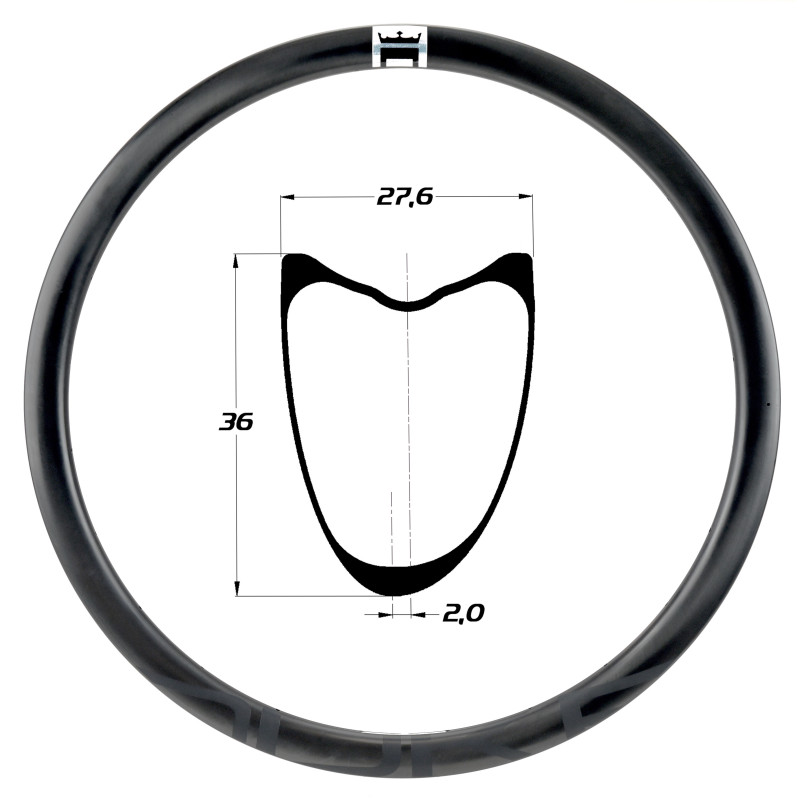

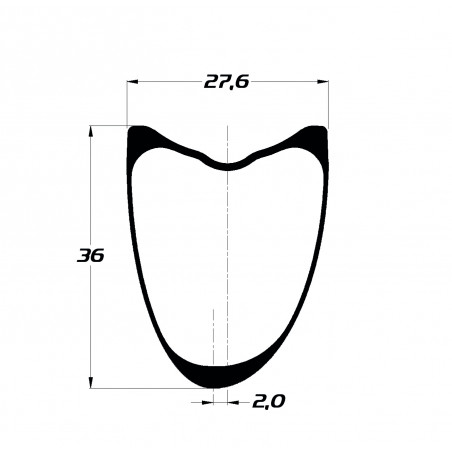

The Baccara X-Machine are carbon rims for tubular adapted to a Cyclo-cross competition use, UCI APPROVED, versatile on all types of surfaces (sand, mud, grass,..) Its width of 27.6mm allows a better fitting of the tubular and thus a gain in grip and performance limiting the risks of detachment of the tubular.

UCI APPROVED

The Baccarat X-Machine rim has passed all UCI tests and is homologated to race on all World Cup races of Cyclocross!

RIM DUKE BACCARA X-MACHINE 36T* DISC

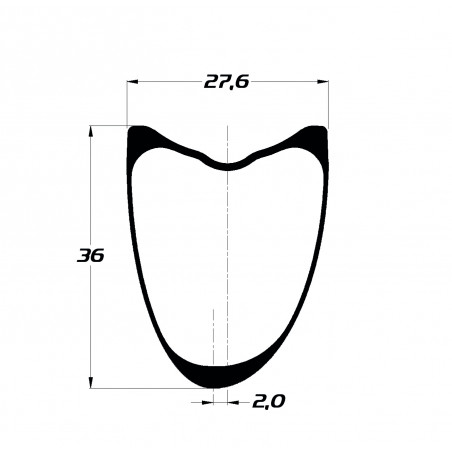

New DUKE carbon UD rim, designed, developed and tested internally. For its wheels, DUKE owns the manufacturing tools! The new DUKE Baccara SLS3* wheels are the latest evolution of the essential 3K Baccara. It is available in 36 mm, disk braking, asymmetric profi. For this new generation, we worked on 3 points: weight, comfort and aerodynamics. Thanks to the SLS3 technology we have lowered the weight by 10%, due to the use of high modulus fibers and a new process of molding in sealed enclosure with resins of new generation. This process also allows better filtration of vibrations generated by the particle size of the bitumen. The comfort is improved. The width is larger with 27.6 mm. This gives more volume to the hoses and improves performance, comfort and cornering grip. Recommended hose width is 32 mm cyclocross. The profile of the rim has been reworked to improve its aerodynamics and stability in all wind conditions. The outer width is larger with 27.6 mm and has a new warhead shape. This reduces aerodynamic drag and thus increases its speed. The wheels are also less sensitive to side wind and the steering more precise, the cyclist feels more confident. It also retains a version with asymmetrical profile of 2mm. With the increase in the number of speeds, the cassette side flange of the hub is seen more and more recentered towards the inside of the wheel. The umbrella spokes opens further and this reduces the stability and lateral stiffness of the wheel: it is fuzzy in the raises, takes sail easily. Asymmetry gives an umbrella much higher than the symmetrical rims and rebalances the tensions of the two plies for more rigidity and durability.

* (T for Tubular, gut and SLS3 for Super Light Series 3nd generation)

Technology

A design optimized for the demands of road and gravel riding

- Aerospace-grade resin and optimized carbon fiber lay-up

- Up to 10% lighter and stronger than the previous SLR1 version

- Tuned vertical compliance for more comfort and responsiveness

Aerodynamic optimization through CFD (Computational Fluid Dynamics)

- Optimized tire-to-rim transition to reduce aerodynamic drag

- Greater stability in crosswinds

- Compatible with wide tires without compromising rolling efficiency

Controlled vertical flex and rebound

- More dynamic handling during weight transfers and bermed corners

- Increased comfort on rough terrain

- Reduced energy loss, more speed and efficiency

Maximizes tire volume and performance

- Enables lower pressures without sacrificing rolling efficiency

- Controls tire deformation for greater stability

- Improves control and comfort on all terrains

A varnish-free finish process

- Reduces VOC emissions and carbon dust during production

- More scratch-resistant surface

- Naturally glossy finish

Asymmetrical spoke lacing

- Balances spoke tension on both sides

- Improves lateral stiffness, stability, and long-term durability

- No added weight

Data sheet